AISI ASTM A249 SS 201 304 Edelstahl

Holen Sie sich aktuelle Preis| Zahlungsart: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transport: | Ocean,Land,Express |

| Zahlungsart: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transport: | Ocean,Land,Express |

Modell: 201 304 304L 316 316L 301 321 410 420 441 439 409L

Standard: JIS, AiSi, ASTM, GB, LÄRM, DE

Herkunftsort: China

Spezies: Geschweißt

Material: Serie 200, 300er Serie, Serie 400, 600er Serie

Zertifizierung: RoHS, ISO, IBR, BV, Sgs

Schweißform: Spiralgeschweißt, ERW, Efw

Toleranz: ± 1%

Verarbeitungsservice: Biegen, Schweißen, Abwickeln, Stanzen, Schneiden, Formen

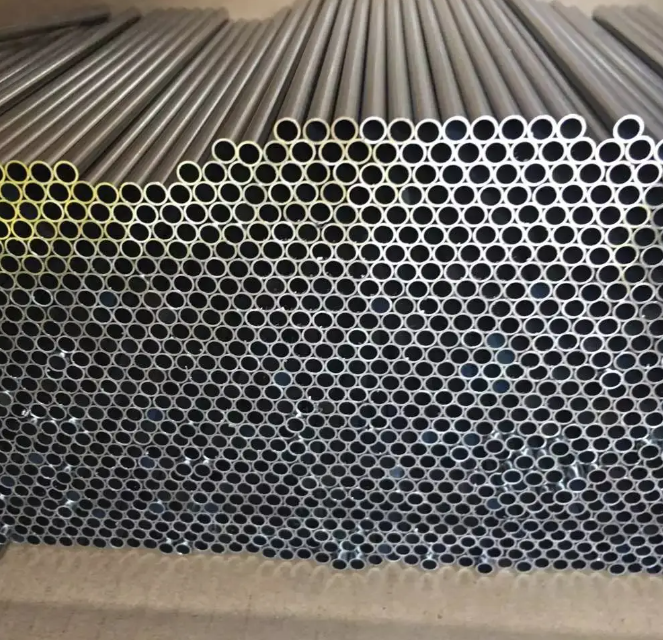

Product Name: Stainless Steel Welded Round Pipe

MOQ: 1 ton

Keyword: Stainless steel pipe

Technique: Hot Rolled Or Cold Rolled

Length: 1-12m or customized

Lieferzeit: 15-30 days

Production Process: welding/ polishing

Size: customized

Surface Finish: 2B

Invoicing: by actual weight

| Verkaufseinheiten | : | Kilogram |

| Bildbeispiel | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

|

Material

|

Stainless Steel 304/304L/316L

|

|

Shape

|

Round / Square / Rectangle

|

|

Production Standards

|

ASTM A270, ASTM A269, ASTM A249, ASTM A778, ASTM A789, DIN 11850, EN 10357, EN 10217-7 and so on.

|

|

Size

|

Outer diameter = 16 - 2000mm ;

Thickness = 0.8 - 20 mm ; Length = 6 - 18.3 meter ; Or as customer' s request. |

|

Tolerance

|

According to the Standard , +/-10% Commonly ;

|

|

Surface Treatment

|

180#, 320#, 400# Satin / Hairline, Bright Anneal, Pickle,400#, 500#, 600# or 800# Mirror finish

|

|

Process Characteristics

|

Inner Welded Seam Removed ; Online Bright Solution Anneal ; Inner Electro Polish And Mechanical Polish ;

|

|

Application

|

Petrochemical Industry ; Chemical Fertilizer Industry ; Oil Refining Industry ; Oil And Gas Industry ; Light Industry And Food Industry ; Pulp And Paper Industry ; Energy And Environmental Industries .

|

|

Test

|

Flaring test ; Flattening test ; Bending Test ; Hydraulic Test ; Eddy Current test

|

|

Design

|

OEM / ODM / Customized

|

|

Certificate

|

ISO9001 ; ISO14001; ISO 18001; TUV ; SGS

|

|

Stainless Steel Mechanical Properties

|

||||||

|

Grade

|

Tensile Strength

|

Yide Strength

|

Elogation

|

Hardness

|

Solution

Annealing

|

|

|

kgf/mm²(N/mm²)

|

kgf/mm²(N/mm²)

|

%

|

HRB(HV)

|

ºC

|

||

|

ASTM

|

TP 304

|

≥53 (515)

|

≥21 (205)

|

≥35

|

≤90 (200)

|

1040ºC-1150ºC

Water Quenching

|

|

TP 304L

|

≥50 (485)

|

≥17 (170)

|

||||

|

TP 316

|

≥53 (515)

|

≥21 (205)

|

||||

|

TP 316L

|

≥50 (485)

|

≥17 (170)

|

||||

|

JIS

|

SUS 304

|

≥53 (520)

|

≥21 (205)

|

1010ºC-1150ºC

Water Quenching

|

||

|

SUS 304L

|

≥49 (480)

|

≥18 (175)

|

||||

|

SUS 316

|

≥53 (520)

|

≥21 (205)

|

||||

|

SUS 316L

|

≥49 (480)

|

≥18 (175)

|

||||

|

GB

|

06Cr19Ni10

|

≥53 (520)

|

≥21 (210)

|

1010ºC-1150ºC

Water Quenching

|

||

|

022Cr19Ni10

|

≥49 (480)

|

≥18 (180)

|

||||

|

06Cr17Ni12Mo2

|

≥53 (520)

|

≥21 (210)

|

||||

|

022Cr17Ni12Mo2

|

≥59 (480)

|

≥18 (180)

|

||||

|

EN

|

1.4301

|

(500-700)

|

≥20 (195)

|

≥40

|

1000ºC-1100ºC

Water Quenching

|

|

|

1.4307

|

(470-670)

|

≥18 (180)

|

||||

|

1.4401

|

(510-710)

|

≥21 (205)

|

1020ºC-1120ºC

Water Quenching

|

|||

|

1.4404

|

(490-690)

|

≥19 (195)

|

||||

|

Austenitic Stainless Steel

|

201, 301, 304, 305, 310, 314, 316, 321, 347, 370, etc

|

|||

|

Martensitic Stainless Steel

|

410, 414, 416, 416, 420, 431, 440A, 440B, 440C, etc

|

|||

|

Duplex Stainless Steel

|

S31803, S32101, S32205, S32304, S32750, etc

|

|||

|

Ferritic Stainless Steel

|

429, 430, 433, 434, 435, 436, 439, etc

|

|||

|

chemical component ( %)

|

|||||||

|

Grade ASTM

|

C

|

Si

|

Mn

|

S

|

P

|

Cr

|

Ni

|

|

201

|

≤0.15

|

≤0.75

|

5.50-7.50

|

≤0.030

|

≤0.060

|

16.00-18.00

|

3.50-5.50

|

|

304

|

≤0.07

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

17.00-19.00

|

8.00-11.00

|

|

304L

|

≤0.03

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

18.00-20.00

|

8.00-12.00

|

|

309S

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

22.00-24.00

|

12.00-15.00

|

|

310S

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

24.00-26.00

|

19.00-22.00

|

|

316

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.045

|

16.00-18.00

|

10.00-14.00

|

|

316L

|

≤0.03

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

16.00-18.00

|

12.00-15.00

|

Produktionsprozess von Edelstahlrohr: Runde Stahlvorbereitung - Heizung - Heißes Rolling -Piercing - Kopfschnitt - Pickling - Schleifen - Schmiermittel - Kaltrollverarbeitung - Entfette - Lösungswärmebehandlung - Richtung - Rohrschneiden - Pickling - Fertigproduktinspektion.

Es wird häufig in industriellen Übertragungsleitungen und mechanischen Strukturteilen wie Erdöl, chemische Industrie, verwendet

Medizinische Behandlung, Lebensmittel, Lichtindustrie, Maschinen und Instrumente.

FAQ

F: Was ist Ihr Vorteil?A: Natürlich werden alle unsere Produkte vor der Verpackung streng auf Qualität getestet, und uneingeschränkte Produkte werden zerstört.

Andere Produkte: 304 Edelstahl Roundstange, ASTM Edelstahl Roundstangen, Kohlenstoffstahl nahtloses Stahlrohr, Kohlenstoffstahlrohr, Kochkohlenstoffstahl -Nahtstahlrohr, Kupfer, DX51 -verzinktes Rollen, verzinkte Spuelle, verzinktes Rohr

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.